What Is the Difference between Pickling & Passivation?

The key

difference between Pickling and Passivationis that

pickling is the process we use to remove impurities on a metal surface, while

passivation is the protection of a metal surface against corrosion. We also use

the term pickling when it comes to food. Here, pickling is a form of surface

treatment of metals. On the other hand, passivation is making a material

"passive" to corrosion. Unlike pickling, here we protect the surface

of the metal before it becomes impure.

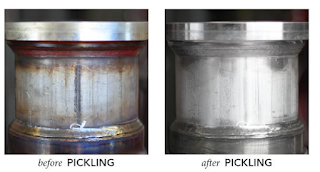

What is Pickling?

Pickling

is the process of treating metal surfaces to remove any impurities on the

surface. Impurities can include stains, rust, scale, inorganic contaminants,

etc. Iron and its alloys, silver, copper, aluminium, brass are a few examples

of metals that undergoes this process.The chemical agent we use in this process

is "pickle". It usually contains acids. It also contains other

ingredients, such as wetting agents, corrosion inhibitors, etc.This pickling

process is common in cleaning steel surfaces in steel making processes. The

need for this process is to remove substances on the metal surface that can

affect further metal processing such as plating and painting. De-scaling is an

important step in this process. Many hot working processes leave a layer of

discolouring oxide on the metal surface. We can remove this layer of

encrustation by immersing it in a vat of brine.

Pickling

techniques

In general, most Pickling

Companies use three different techniques: the mechanical pickling, the

chemical pickling and pickling electrolytic or electrochemical. Mechanical

pickling involves the mechanical removal of impurities present on the surface

of metals by abrasion. Chemical pickling is carried out by means of spray,

brush or immersion pickling agents by putting the surfaces in contact with ad

hoc chemical solutions. The electrolytic or electrochemical pickling involves

the use of chemical solutions together with the supply of electric current with

an appropriate waveform, which optimizes and speeds up the treatment of the

metal.

Some

information on passivation

Corrosion is the main enemy of all metals. It is

formed when common steels react with the environment creating a surface

containing iron oxide. This very porous surface allows the oxidation process to

continue, penetrating into the steel. The corroded surface will produce what is

usually referred to as rust.The term passivation refers to an electrochemical

phenomenon aimed at slowing down or preventing the corrosion of metallic

materials and metal alloys.

ALT=Pickling

and Passivation

The company specializing in passivation leads to the

passivity of the metal material. In particular, the phenomenon of corrosion is

stopped. The final result is a metal with zero corrosion speed. This is a

phenomenon caused by the continuous dissolution and regeneration of the

passivation film.The passivation layer formed by the use of baths with a

content of 15% -20% nitric acid are more homogeneous and have oxides-hydroxides

more rich in chromium.Passivation brings several advantages –

· Improves corrosion resistance

· Gives a uniform and smooth finish / appearance

· Makes the surface shiny

· Allows easier cleaning

· Helps to give the product a greater life.

Comparison and characteristics

In the

industrial sector, the surface of the stainless steel work piece must be

machined to improve its quality. There are many processes of surface treatment

of stainless steel, such as passivation, pickling, rust proofing, polishing,

galvanizing, electrophoresis, etc. The most commonly used is the Pickling and Passivation solution. The

surface treatment of stainless steel pickling passivation is very convenient.

Of course, different manufacturers will choose a suitable surface treatment

based on their manufacturing process.

First, we

explain the role and characteristics of the solution. When working with the

surface of stainless steel parts, the whole stainless steel part is mainly

immersed in the passivation solution until the surface of the stainless steel

parts is completely uniform. After this process, the stainless steel part then

rinse with clean water. In this way, the surface of the machined work piece

will achieve a uniform colour and a beautiful surface will be obtained. This

type of processing method is increasingly extended in the application. And the

stainless steel pickling and

passivation solution can be recycled and used without evaporation,

non-volatile, no yellow smoke and hydrogen embrittlement, so the operating

environment is good and does not require special equipment.

Conclusion

Metals are most of the time

very reactive when we expose them to normal air. And, through proper Chemical

Cleaning it is possible to protect the entire metal surface. Pickling and

Passivation are two techniques we can use to protect the metal

surface. Pickling is the process of treating metal surfaces to remove any

impurities on the surface. We can do this using pickled liqueur. In this way it

protects a metal surface from impurities on the metal surface. Passivation is

the process of making a material "passive" to corrosion. Furthermore,

passivation is sometimes spontaneous and natural, or we can do it through a

chemical reaction. Furthermore, it protects the metal surface even before it is

exposed to normal air.

Comments

Post a Comment